Two weeks ago I ran a webinar together with my colleague Mathias Gustafsson on what has happened with our cloud service over the past year. If you are interested in the technical details you can still watch it on-demand here.

But during the webinar I also gave a brief reflection on what we’ve heard when talking to companies, mostly in the Nordic region, on topics like Cloud adoption, need for 3D support and pains in supply chain communication. I thought it could be useful to write this down in an easy to read article. So here it is, enjoy. :)

Cloud adoption?

About one year ago, we launched ShareAspace as a Cloud service. A low touch, no code alternative. Just a plain cloud subscription. How was it received? In general companies are interested and positive towards cloud. Many are already using CRM and ERP in the cloud. But there is still reluctance towards sharing your core design data in the cloud. You get the feeling that some companies still feel it is safer to create a zip-package with all the drawings and send it via email.

There is also still a big difference between the big OEMs and 1-tier suppliers compared to small and medium sized suppliers. The SMBs have already fully embraced the Cloud offerings out there, e.g. Office365 and others. Medium sized businesses are very positive but are in some cases stuck in the classic purchasing of IT-services and software while the bigger Suppliers and OEMs are well aware of the benefits of a SaaS offering but have often invested heavily in custom solutions and hence need to plan their roll-out of a Cloud service.

To summarize, companies we talk to are very positive towards cloud and even if we sense some reluctance still, it will revolutionize the supply chain collaboration area area quite soon as well.

How is 3D relevant for SMB

I have no official statistics on this but the feeling when we’ve talked to companies during the spring is that this varies a lot! To some it is critical. 3D is the only option. Others still rely heavily on 2D drawings. But most are saying its a mix. My personal reflection on this is that it’s a generation thing. This revolution started 20-30 years ago in the big OEMs. 1st and in many cases 2nd tier suppliers are already adapted to 3D and do all of their designs and downstream process in 3D. The smaller suppliers, where the manufacturing is more of a craft has not really had the same need, yet! This is changing as well and my guess is that in 5-10 years this has changed completely. It all comes down to cutting lead time and increasing automation. 3D is now not only used in traditional CAM processes for cutting and milling etc. but also in additive manufacturing and high quality inspections of delivered products.

So for sure, 3D is relevant already today and will become increasingly relevant in the coming 3-5 years!

What are the pains in Supply chain communication?

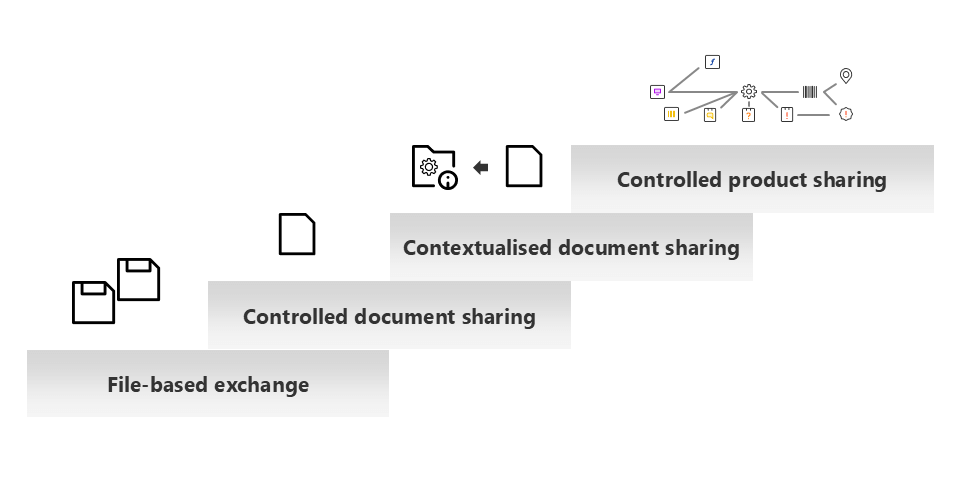

I actually wrote a blog post on this a couple of weeks ago. And the actual problems with supply chain communication is no different from communication of information in any other stage of product life cycle or with any other type of person. The difference here is that you engage suppliers because you want them to do what they are good at but still not employ them. Same reason you use consultants. You want to use their services without revealing everything. You want to keep a good and friendly relationship with them, but at an arms length!

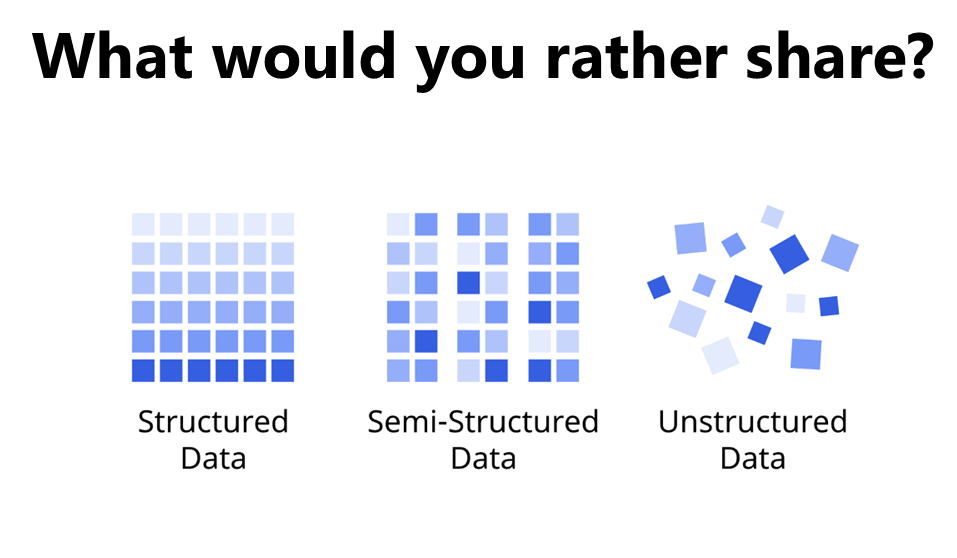

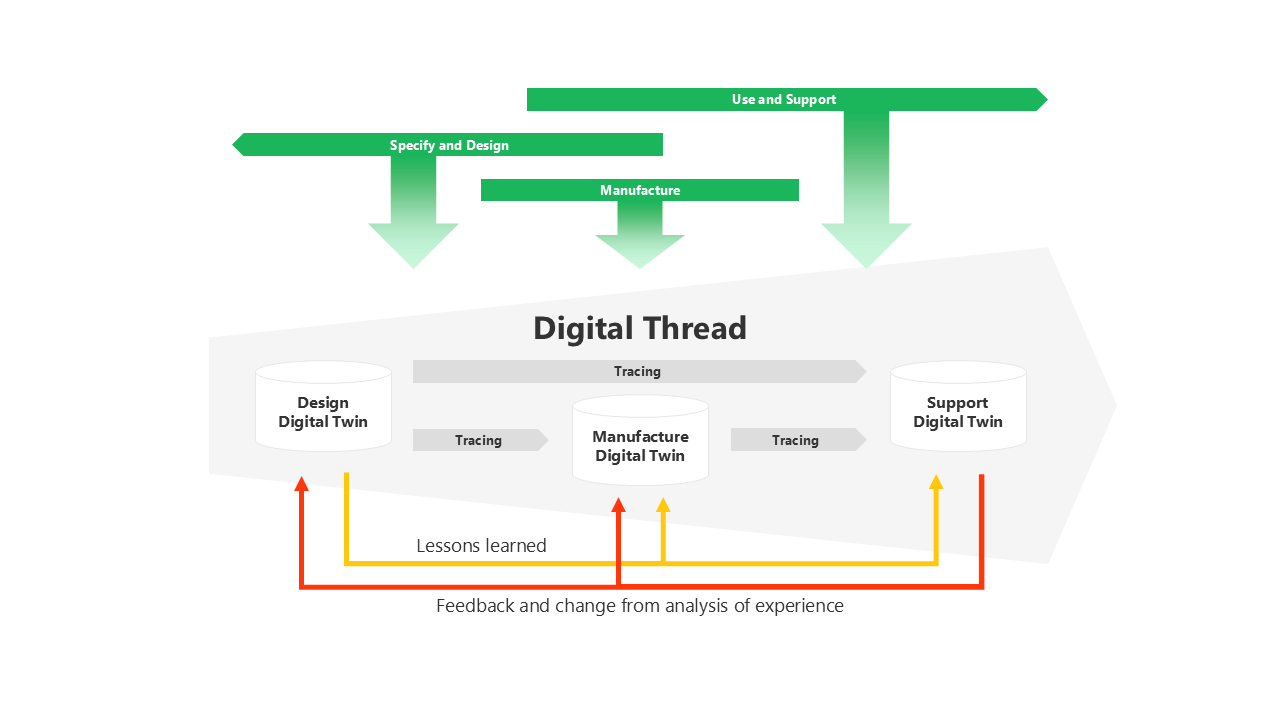

One thing that makes this difficult is when you are producing a complex product or system. Products that consist of many parts, probably it involves several different disciplines like hardware, software, electronics, mechatronics, etc. This in itself drives the complexity of several teams working together and immediately configuration and version control becomes an issue. If you then add the layer of having to share this information with partners and suppliers that you want to keep on arms length, it is considered a pain!

Other things that is considered pains with this is when you start getting a larger supply network. Having one common way of communicating with your suppliers is crucial to get this to work. The big OEMs, of course having had big supply chain networks for many decades have invested in such solutions over the years. Now, first and second tier suppliers are looking at this with jealousy but are not willing to invest in developing a bespoke solution. So perhaps if there was a solution available out there. Simple, cheap and online…

A third thing we’ve noticed is the increased demand for detailed information on certifications, protocols, performed operations etc. on every single batch, well even down to indivdual components. This could be referred to as component provenance. And since the big OEMs have this requirement for their certifications, e.g. in aerospace industry, this requirement is pushed down to both first and second tier suppliers. So when their supply network expands, they need to force these requierments on their suppliers BUT ALSO be able to handle all the documentation that goes with it.

So why isn’t this solved yet?

Well for one, it is not a super easy thing to do. Secondly, it has, at least until now required costly IT investments. Some have taken that cost. Others have not yet done that.

But mostly, I think, again not statistically proven but still, this is an issue that spans several departments. And as always, when more than one department is involved in a project it’s a lot harder to get something into production. This relates to cost obviously but also to level of details, processes and ultimately people.

Magnus Färneland, Eurostep