BIM and the Digital Twin

The use of Building Information Models [BIMs] is changing the way the Architecture, Engineering, and Construction [AEC] industries will operate in the future. Data from different disciplines and the early phases of design and construction will be reused downstream and during the entire building life cycle. The Internet of Things [IoT] will augment the BIM revolution and allow for real-time feedback during building use. The application of Digital Twins in AEC will bring BIM and IoT together. This digital transformation will facilitate new business models and new ways to optimize the use of capital, material, energy, and other resources.

By collecting it in a single repository, data from silos can be brought together, integrated, and consolidated. This allows for a better overall understanding of assets and their use, enabling owners and operators to make more informed decisions.

In future, the integration of data will support the views of different actors involved over the complete life cycle of a building. Reusing data has the potential to eliminate manual data re-entry and, thereby, drastically increase data quality.

The need for a standards-based approach

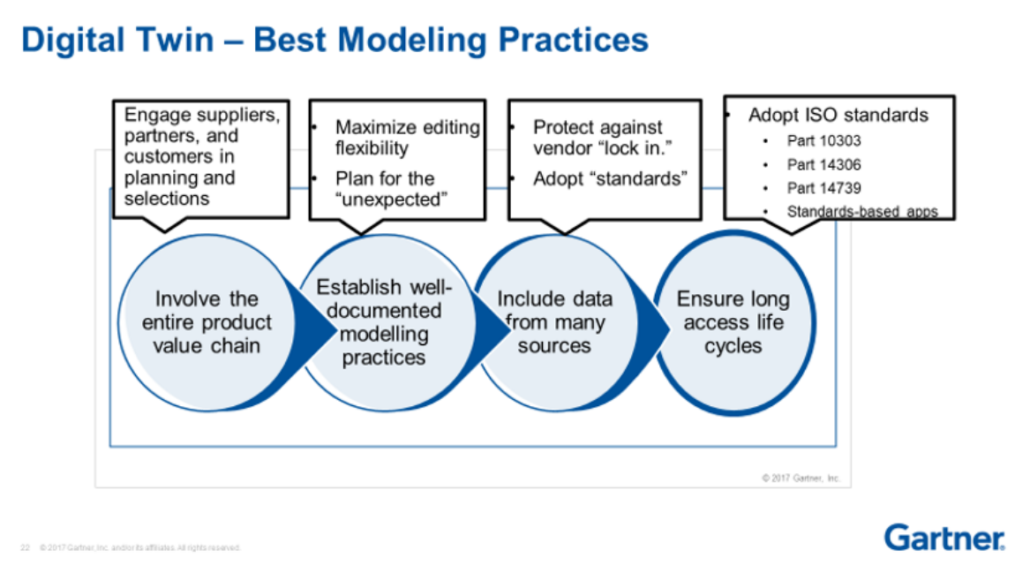

Building a “system” to support Digital Twins and related technologies is a significant investment. In a presentation at PDT Europe 2017, Marc Halpern from Gartner emphasized this point in a presentation entitled “Busting the Myth of Digital Twins and Planning Them Realistically”. He raised the issue of vendor lock-in and recommended the use of standards in order to avoid this problem.

For the AEC and BIM domains, the Industry Foundation Classes [IFC] standard has been successfully established for the exchange of BIM data across domains, software applications and organizations. In order to extend IFCs to include a life cycle view, the natural choice of a standard would be ISO 10303-329 also referred to as the “Product Life Cycle Support” [PLCS] standard. As many buildings and AEC assets have a long lifetime, the case for using information standards is even more compelling and obvious than in other industrial domains.

By adopting commercial software like ShareAspace – which implements the PLCS standard – the capabilities described are available “out of the box”. PLCS covers the complete lifecycle of a product or system from the specification of early ideas and requirements, through design and build, to reuse and disposal – including upstream feedback.

Preparing for the BIM Digital Twin

A Digital Twin can be seen as the digital representation of a physical thing, from a BIM perspective. It is represented using the information entities that reside in the “AsRealized” life cycle phase.

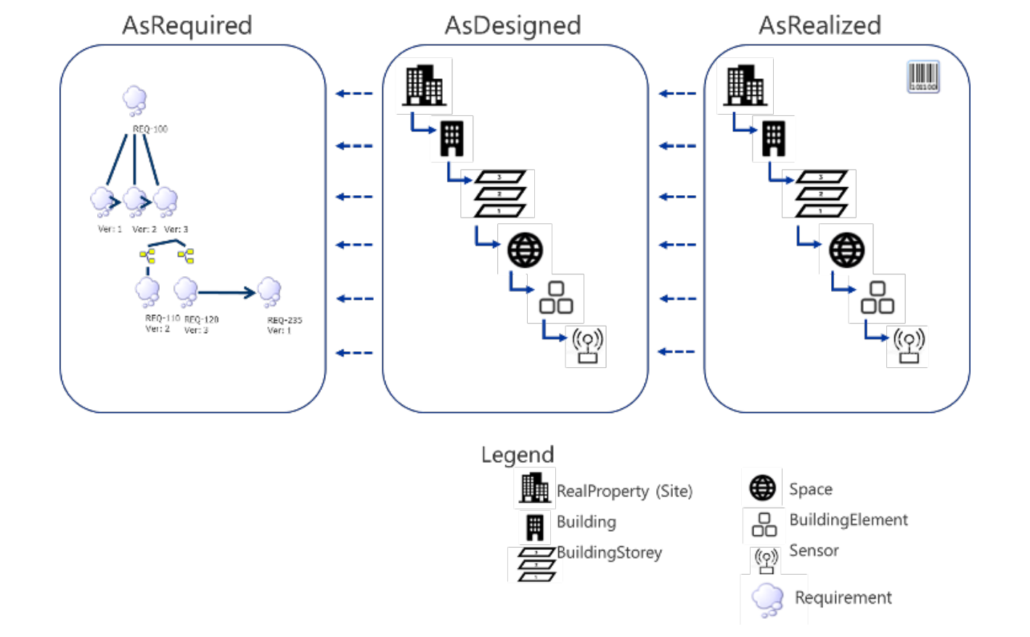

The diagram above depicts a simplified life cycle model that has brought the key business objects of an IFC-based BIM into a life cycle context. For example, when creating the design of a building, there will be instances created for the RealProperty, Building, BuildingStorey, Space, BuildingElement and Sensor business objects defined for the AsDesigned domain. When construction takes place, instances of the AsRealized business objects will be created. During design, sensors could be placed inside a building. These sensor design instances are not the same as the real (purchased) sensors that are installed in the building during construction.

Bringing BIM and IoT together

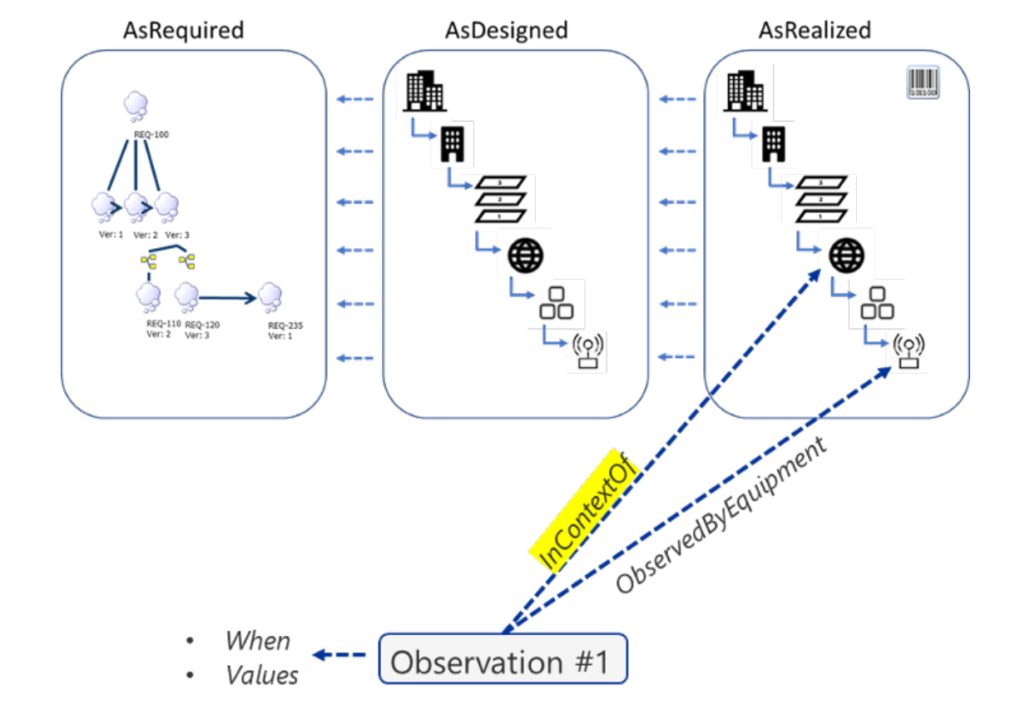

To connect BIM with the real world, the actual sensors and their measured values have to be represented in the BIM database and/or data lake. In the AsRealized domain, there are information entities that can represent observations with measured values and other information such as timestamps and descriptive files However, since a sensor can emit many, many values it would make no sense to store all of these in a digital twin used to manage the BIM lifecycle. Such a system would be flooded with measured values. We need, instead, to define an architecture that can deal with structured data as well as large volumes of unstructured data.

The solution architecture

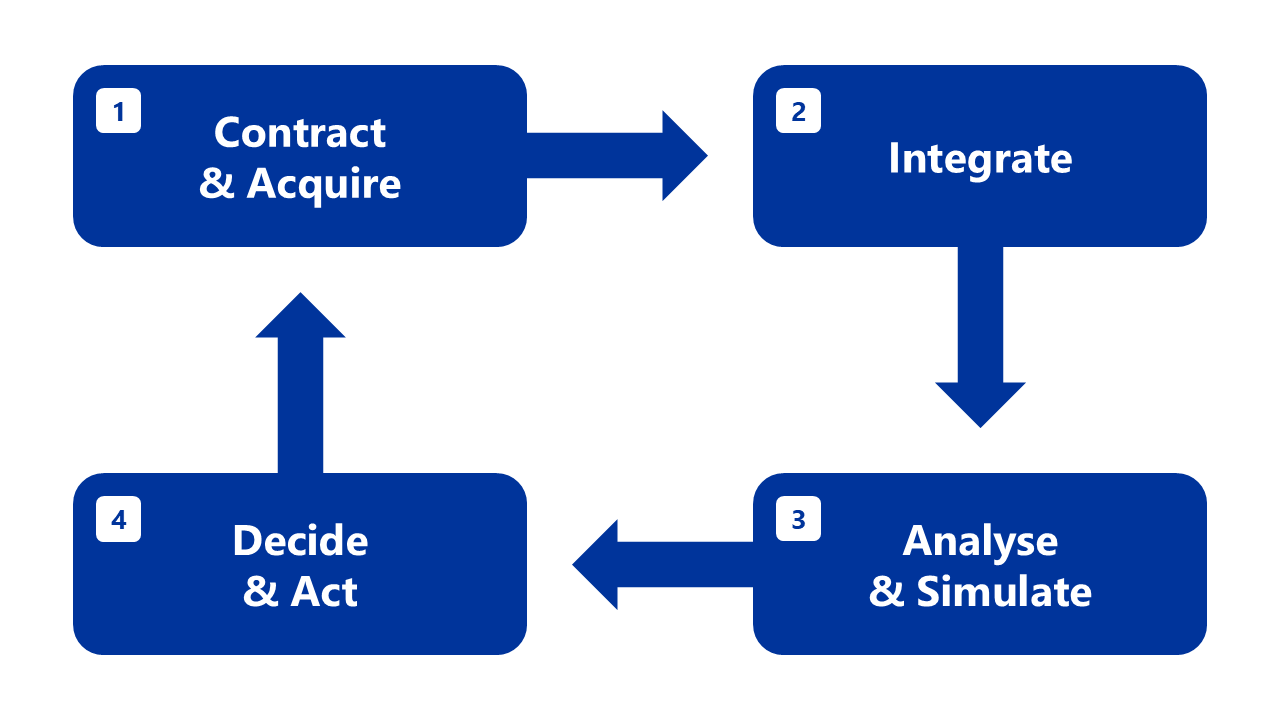

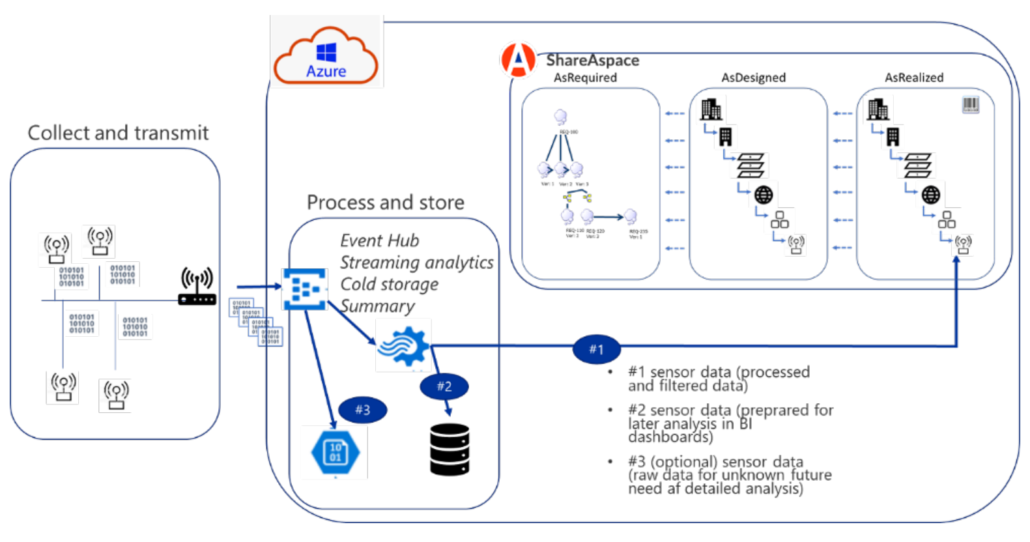

Such an architecture is outlined below:

The real-world sensors reside in the real building and emit their signals inside a “collect and transmit” capability. A variety of existing technology is employed to collect the measured values from the sensors, either in a passive, or an active way. The collected data is also transmitted using existing technology.

The “collect and transmit” capability feeds data from real-world objects into the Azure cloud by using Azure services such as:

- Event Hub, which receives the data using various connectors to read the data according to which technologies are used.

- Streaming analytics are used to process the incoming data stream and to select the data that will be managed by the BIM objects mastered in ShareAspace.

Streaming analytics can also be used to process the raw sensor data and transform it into something that can be consumed and presented by, for example, Business Intelligence [BI]. If there is a need to access all the raw data for future analysis, then “cold storage” using an Azure Data Lake can be used.

Processed sensor data that is stored in ShareAspace is represented using an information entity, that is part of the life cycle management information model based on PLCS. Sensor data in its raw format contains values and a minimal set of metadata, such as timestamps and references to the sensors that provided the values. This raw data needs to have more explicit semantics to be useful in different contexts. For example, the property that the value represents; the unit used to measure the value, the objects to which the value is assigned, when the value is effective etc.

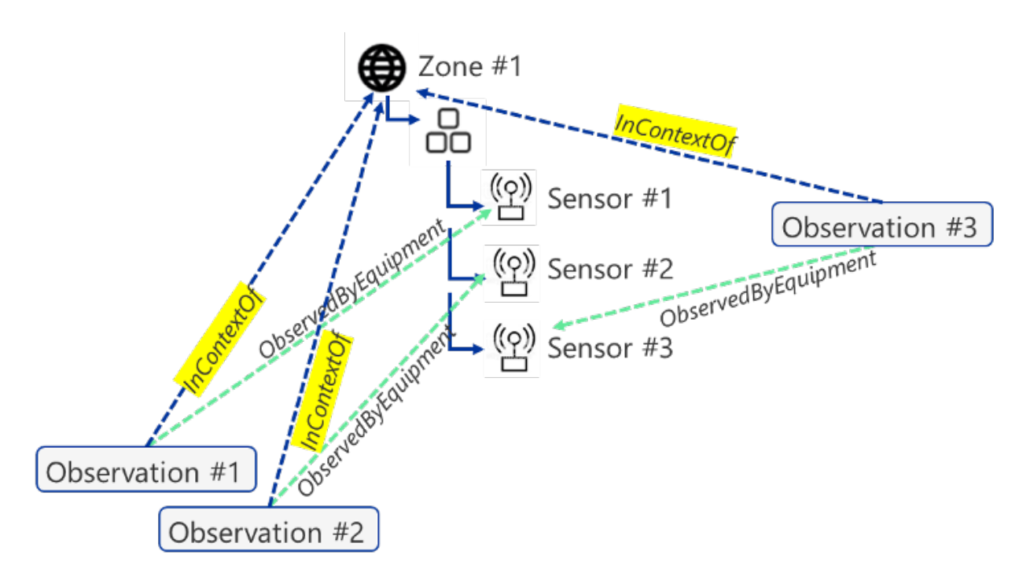

Once the sensor data builds the digital twin that is managed in ShareAspace, information can be aggregated. For example, temperature sensors emit values to the sensor digital twin which knows that it is serving a BIM space. The BIM space object can make inferences by analyzing data from the sensors that serve the space. It should be noted that the aggregated information can be deduced from different sensor types. For example, a zone object can have a property that is the result of combining different measures of air quality from different types of sensors.

Exploiting the aggregated information

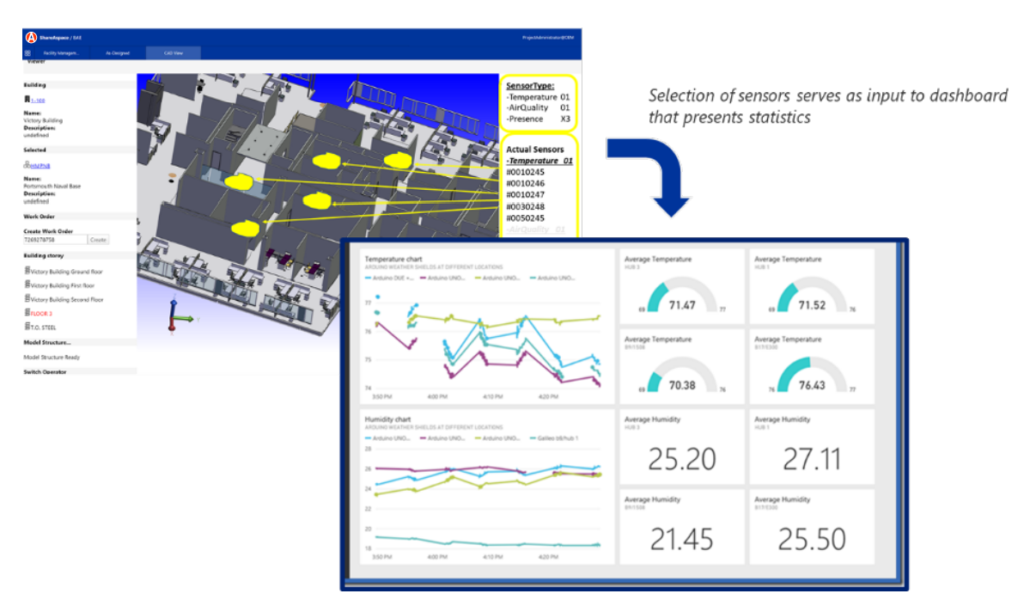

Using ShareAspace to manage the BIM data also allows users to have a single vantage point from which they can access different in-context views. For example, a digital mock-up that combines structural data (the BIM business objects and their spatial and non-spatial relationships) with a geometrical view and a dashboard for the sensor data.

Taking the plunge into the data lake

The additional benefit of this solution is that the raw sensor data can be accessed to discover more details and to provide answers to future queries which are not currently anticipated. The structured data facilitates the narrowing down of the raw data so that it may serve as a starting point for further elaboration. Once the elaboration is complete, the findings can be fed back as structured data.